Every successful ecommerce order goes through a series of carefully coordinated steps before it reaches the customer’s doorstep.

This behind-the-scenes process, from the moment an order is placed online to the moment it’s delivered, is known as the order fulfillment workflow.

In simple terms, the order fulfillment workflow is the system that manages how orders are received, processed, picked, packed, shipped, and sometimes returned. It’s the operational backbone of ecommerce, ensuring that every purchase turns into a smooth, reliable delivery experience.

When managed well, this workflow keeps customers happy, costs under control, and operations scalable. When it’s inefficient, the opposite happens: delayed shipments, stock errors, and increased costs that cut into profit margins.

For growing ecommerce brands, understanding how this process works, and where it can be improved, is crucial to staying competitive.

That’s where ShipBuddies comes in.

As a technology-driven 3PL (third-party logistics) partner, ShipBuddies simplifies every stage of the fulfillment process through automation, real-time visibility, and nationwide scalability.

Whether you’re shipping 100 or 10,000 orders a month, ShipBuddies’ workflow solutions are built to help you scale efficiently.

Quick Definition: The order fulfillment workflow is the end-to-end process of receiving, processing, and delivering customer orders in ecommerce from warehouse to doorstep.

Why the Fulfillment Workflow Matters for Ecommerce Sellers

Behind every five-star customer review, there’s a ecommerce order fulfillment service and workflow doing its job flawlessly.

For ecommerce sellers, this process isn’t just a back-end operation, it’s a core business driver that directly impacts profitability, growth, and brand reputation.

When your fulfillment system runs smoothly, customers receive their orders faster, inventory stays accurate, and your operational costs remain predictable. But when the workflow breaks down, due to delays, mispicks, or poor tracking, even the best product or marketing campaign can’t make up for a bad delivery experience.

1. It Shapes the Customer Experience

Customers don’t see the warehouse, the software, or the carrier. They see the result.

An efficient workflow ensures on-time delivery, accurate packaging, and real-time tracking updates.

In contrast, delays or incorrect shipments damage trust and often lead to costly returns or negative reviews.

Fact: 84% of shoppers say they’re unlikely to buy again after a poor delivery experience.

2. It Controls Costs and Margins

Fulfillment inefficiencies add up quickly.

Extra labor hours, disorganized picking, and incorrect packaging sizes can inflate your cost per order (CPO), reducing your profit margin. A streamlined workflow reduces manual touchpoints and uses automation to lower per-order costs as your business grows.

3. It Enables Scalability

As order volume increases, so do fulfillment challenges.

Without an optimized workflow, scaling becomes chaotic, more orders simply mean more mistakes.

With automation, proper warehouse layout, and reliable partners like ShipBuddies, scaling your operations becomes predictable and profitable.

4. It Strengthens Brand Loyalty

Fast, accurate, and transparent order fulfillment makes customers confident in your brand.

That confidence leads to repeat purchases and word-of-mouth referrals, two of the most powerful (and cost-effective) growth drivers in ecommerce.

In short: Your fulfillment workflow isn’t just about logistics. It’s about customer satisfaction, brand perception, and long-term profitability.

ShipBuddies helps ecommerce brands achieve this balance with data-driven fulfillment systems that optimize cost, accuracy, and speed, all without compromising customer experience.

Step-by-Step: The Order Fulfillment Workflow

Every ecommerce order passes through a series of structured, repeatable stages that transform an online purchase into a delivered package. Understanding these stages and how to optimize each one is key to building an efficient, scalable fulfillment operation.

Below is a detailed look at the six primary stages of the order fulfillment workflow.

Step 1: Receiving Inventory

The process begins long before a customer places an order. When new products arrive from manufacturers or suppliers, they’re checked, counted, and stored in the fulfillment center.

Key tasks include:

- Verifying SKUs and quantities against purchase orders.

- Labeling and organizing items by location for easy access.

- Updating stock levels in your warehouse management system (WMS).

Efficiency Tip: Accurate receiving prevents stockouts and order errors later.

Step 2: Order Processing

Once a customer makes a purchase, your ecommerce platform automatically sends that order to the fulfillment system. The order processing phase ensures that each order is validated, verified, and queued for fulfillment.

This stage includes:

- Capturing and confirming order details.

- Checking stock availability.

- Prioritizing by order type (standard, express, or bulk).

- Sending pick lists to warehouse teams or automation systems.

ShipBuddies integrates directly with major ecommerce platforms like Shopify, WooCommerce, Amazon, and Etsy, ensuring real-time order syncing and automated workflow routing.

Step 3: Picking Inventory

Picking is the heart of the fulfillment operation, and often the most time-consuming. Warehouse staff (or robots) locate and retrieve items from their storage locations based on digital pick lists.

Best practices include:

- Batch picking (grouping similar orders).

- Zone picking (assigning staff by warehouse area).

- Using barcode or RFID scanners for speed and accuracy.

ShipBuddies uses optimized picking routes and scanning technology to make sure every order is correct and efficient.

Step 4: Packing Orders

Once items are picked, they move to the packing station. Here, products are securely packaged, labeled, and prepared for shipment.

Smart packing involves:

- Choosing the right-sized box to reduce DIM-weight shipping costs.

- Adding protective materials without excessive waste.

- Including packing slips, inserts, or branded materials.

- Weighing and sealing packages accurately.

ShipBuddies’ standardized packaging system ensures protection and cost efficiency, so every box looks professional while minimizing material waste.

Step 5: Shipping and Delivery

This is where your fulfillment workflow meets your customer. Shipping optimization involves choosing a carrier, printing labels, and ensuring the package arrives safely and on time.

Core tasks include:

- Selecting the best carrier for destination and cost.

- Generating and affixing shipping labels automatically.

- Providing customers with real-time tracking updates.

Step 6: Returns and Reverse Logistics

Even with perfect operations, returns are inevitable. A clear, efficient reverse logistics process protects customer trust and recovers value from returned inventory.

This step involves:

- Receiving and inspecting returned items.

- Updating inventory levels.

- Issuing refunds or replacements.

- Repacking items for resale when possible.

ShipBuddies automates return authorization and restocking workflows, giving both merchants and customers transparency from start to finish.

Summary:

From receiving to returns, every step in the order fulfillment workflow affects speed, accuracy, and customer satisfaction. When optimized, the result is lower costs, fewer errors, and a better experience, for both the seller and the buyer.

How Technology Streamlines the Fulfillment Workflow

For modern ecommerce brands, technology is the difference between a fulfillment process that struggles to keep up, and one that scales effortlessly. Automation, real-time data, and system integration are the foundation of a smart, efficient, and scalable fulfillment workflow.

Let’s break down how technology enhances every stage of fulfillment.

1. Warehouse Management Systems (WMS) Improve Inventory Control

A warehouse management system (WMS) keeps your inventory data accurate and accessible across all sales channels. It tracks where every item is stored, when it moves, and how quickly it’s selling — all in real time.

WMS capabilities include:

- Automated SKU tracking and cycle counts.

- Smart inventory placement based on order velocity.

- Seamless integration with ecommerce platforms (Shopify, WooCommerce, Amazon, etc.).

- Instant updates when stock runs low or replenishment is needed.

Impact: Businesses using integrated WMS software see up to 30% fewer stockouts and 25% faster order turnaround times.

2. Automation Reduces Manual Labor and Errors

Manual data entry and paper-based systems slow everything down. Automation eliminates repetitive tasks like order import, label creation, and shipment confirmation, saving time and cutting human error.

Examples of automation in fulfillment:

- Orders automatically flow from your online store to the warehouse system.

- Barcode scanners confirm item accuracy before packing.

- Smart sorters route packages to the right carrier lane.

With automation, staff focus on quality control and exception handling instead of manual processing.

Efficiency Boost: Fulfillment centers with automation report up to 50% higher throughput per worker.

3. Real-Time Data and Tracking Create Visibility

Visibility isn’t just about knowing where an order is. It’s about control. Real-time dashboards show inventory counts, fulfillment progress, and shipping status at a glance.

This data helps you:

- Identify bottlenecks in the workflow.

- Monitor order accuracy and delivery rates.

- Adjust resources dynamically to meet demand spikes.

4. Predictive Analytics Drive Better Decision-Making

Predictive analytics use historical order data to forecast trends and optimize future performance.

Key applications include:

- Predicting demand surges (like holidays or flash sales).

- Optimizing inventory placement by region.

- Anticipating carrier capacity constraints.

- Reducing overstock and minimizing carrying costs.

Smart Stat: Predictive analytics can cut excess inventory by up to 20% while maintaining fulfillment speed.

5. Integration Across Channels Simplifies Multi-Platform Selling

Omnichannel ecommerce is here to stay, but it can get messy fast without system integration. When your fulfillment platform connects seamlessly with your online storefronts and carriers, you avoid data silos and synchronization delays.

Integrated platforms provide:

- Consistent order data across Shopify, Amazon, and Etsy.

- Unified shipping label and tracking generation.

- Centralized reporting for performance metrics.

ShipBuddies integrates with all major ecommerce platforms, letting you manage every channel’s fulfillment through a single system.

Manual vs. Automated Fulfillment Workflow (Comparison Table)

| Process Area | Manual Workflow | Automated Workflow (ShipBuddies) |

| Order Entry | Manual input from store | Auto-sync from ecommerce platform |

| Inventory Tracking | Spreadsheet updates | Real-time WMS visibility |

| Picking | Paper pick lists | Barcode / smart routing |

| Packing | Human estimation | Dimensional weight optimization |

| Shipping | Carrier website entry | Auto-label & best-rate selection |

| Returns | Manual inspection | Automated RMA & restocking |

Conclusion: Technology doesn’t replace people. It empowers them. The right systems reduce friction, improve accuracy, and give brands the freedom to focus on growth instead of logistics headaches.

Key Metrics That Define Fulfillment Efficiency

You can’t improve what you don’t measure, and that’s especially true in ecommerce fulfillment. Tracking the right metrics helps you identify inefficiencies, reduce costs, and deliver a consistently great customer experience.

These are the core KPIs (Key Performance Indicators) every ecommerce seller should monitor to measure fulfillment performance.

1. Cost Per Order (CPO)

Definition: The total cost of fulfilling an order, including labor, packaging, shipping, and software, divided by the number of orders processed.

Why it matters: A high CPO means your fulfillment process is inefficient or overstaffed. A low CPO indicates scalability and process optimization.

Goal: Keep CPO below $8–$10 for small ecommerce brands and even lower with 3PL automation.

2. Order Accuracy Rate

Definition: The percentage of orders shipped correctly, right item, right quantity, right destination.

Why it matters: Every incorrect shipment costs money twice: once to fix the error, and again in lost trust.

Industry benchmark: 98–99% accuracy.

How ShipBuddies helps: Barcode scanning and verification at each stage ensure near-perfect accuracy and drastically reduce return-related costs.

3. On-Time Delivery Rate

Definition: The percentage of orders that arrive by their promised delivery date.

Why it matters: Late deliveries directly impact customer satisfaction, ratings, and repeat purchases.

Target: 97% or higher on-time delivery rate.

How ShipBuddies helps: With intelligent carrier selection, ShipBuddies reduces transit time, ensures accuracy, and controls shipping costs..

4. Order Cycle Time

Definition: The total time between when an order is placed and when it’s shipped.

Why it matters: Shorter cycle times mean higher customer satisfaction and better capacity utilization.

How ShipBuddies helps: Automation minimizes delays between picking, packing, and shipping, keeping average cycle time under 24 hours for standard orders.

5. Return Rate

Definition: The percentage of orders returned by customers.

Why it matters: A high return rate signals issues in product descriptions, quality control, or packaging. But even when returns are unavoidable, the process must be smooth.

How ShipBuddies helps: Automated return authorizations and restocking workflows reduce manual handling costs and speed up refunds or exchanges.

Fulfillment Efficiency Metrics Summary Table

| Metric | What It Measures | Target Range | ShipBuddies Advantage |

| Cost Per Order | Total fulfillment cost per order | <$10 | Automation + volume shipping discounts |

| Order Accuracy | % of correct shipments | 98–99% | Barcode verification |

| On-Time Delivery | % of on-schedule shipments | ≥97% | Distributed warehouses |

| Order Cycle Time | Time from order to shipment | <24 hrs | Process automation |

| Return Rate | % of returned orders | <5% | Streamlined returns system |

Pro Tip: Track these metrics monthly, not quarterly. Fulfillment inefficiencies compound quickly, early detection prevents costly backlogs and unhappy customers.

The Bigger Picture

Monitoring these KPIs doesn’t just highlight what’s wrong. It reveals what’s working. A steady improvement in accuracy, cost, and cycle time is a clear sign that your fulfillment system is built to scale.

Common Fulfillment Workflow Bottlenecks (and How to Fix Them)

Even the most organized ecommerce operations face fulfillment slowdowns from time to time. As order volumes grow and processes become more complex, small inefficiencies multiply into costly bottlenecks that hurt profit margins and customer satisfaction.

Here are the most common pain points in the fulfillment workflow, and proven strategies to fix them.

1. Inventory Inaccuracy

When your stock data doesn’t match what’s actually on the shelf, fulfillment chaos follows. Mispicks, overselling, and backorders quickly erode customer trust.

Symptoms:

- Frequent “out of stock” notifications after purchase.

- Overfilled or misplaced SKUs.

- Manual inventory counts that don’t align with reports.

Fix: Implement real-time inventory tracking through a warehouse management system (WMS). ShipBuddies automatically syncs inventory across platforms like Shopify, Amazon, and WooCommerce, eliminating manual updates and stock mismatches.

2. Inefficient Picking and Packing

Picking errors and slow packing are among the biggest time drains in ecommerce fulfillment.

Symptoms:

- Employees walking long distances between picks.

- Too many touches per order.

- Incorrect items or quantities shipped.

Fix: Use automated pick lists and optimized warehouse layouts to reduce movement and handling time. Batch-pick similar orders and apply barcode scanning to confirm accuracy. ShipBuddies uses zone-based picking and automation to increase speed and accuracy by up to 30%.

3. Manual Data Entry

Typing order details or shipping information manually invites human error and creates delays.

Symptoms:

- Repeated order entry mistakes.

- Delayed order processing or missed shipments.

- No single source of truth for data.

Fix: Automate your order routing, label generation, and carrier selection through integrated software. ShipBuddies connects directly to your ecommerce store, ensuring orders flow from checkout to fulfillment without manual intervention.

4. Poor Packaging Efficiency

Packaging that’s too slow or inconsistent increases labor time and shipping costs.

Symptoms:

- Overpacked boxes and high DIM weight.

- Inconsistent packaging materials.

- Damaged products during transit.

Fix: Use standardized, right-sized packaging and automated weight verification to reduce waste and cost. ShipBuddies offers pre-calculated DIM optimization to minimize excess materials and shipping expenses.

5. Carrier and Shipping Delays

Shipping delays are often caused by poor carrier coordination, lack of rate optimization, or weak tracking visibility.

Symptoms:

- Late deliveries and unhappy customers.

- High shipping costs for similar routes.

- No visibility once packages leave the warehouse.

Fix: Adopt multi-carrier integration and dynamic rate shopping to ensure the fastest, most cost-effective delivery. ShipBuddies’ network automatically selects the best carrier for each shipment based on delivery zone, weight, and timing.

6. Complicated Returns Management

Returns can quickly overwhelm fulfillment teams when the process isn’t automated.

Symptoms:

- Delayed refunds.

- Poor visibility into return status.

- Returned items lost or not restocked.

Fix: Use automated return authorization (RMA) workflows and real-time restocking updates. ShipBuddies’ system tracks every return from initiation to reintegration, ensuring customers are refunded promptly and inventory stays accurate.

Pro Insight: A bottleneck at one stage affects every other step. Solving just one, like automating picking or improving inventory accuracy, often produces exponential gains throughout the workflow.

Common Bottlenecks & Solutions Summary Table

| Bottleneck | Root Cause | Solution |

| Inventory errors | Manual tracking | Real-time WMS integration |

| Slow picking | Inefficient routes | Batch + zone picking automation |

| Manual data entry | Non-integrated systems | Automated order sync |

| Packaging delays | No standardization | Smart packaging templates |

| Shipping issues | Limited carriers | Multi-carrier rate optimization |

| Return chaos | Manual tracking | Automated RMA + restocking |

ShipBuddies eliminates these bottlenecks by combining automation, data visibility, and logistics expertise, helping ecommerce brands streamline operations without increasing overhead.

How ShipBuddies Simplifies the Fulfillment Workflow

Running an efficient fulfillment operation requires time, space, technology, and expertise. Things that often stretch thin as ecommerce brands grow. That’s where ShipBuddies comes in.

As a full-service 3PL (third-party logistics) partner, ShipBuddies is built to handle every stage of the order fulfillment workflow, from inventory receiving to returns, with precision, transparency, and scalability.

Here’s how ShipBuddies transforms complex logistics into a seamless, scalable system.

1. Streamlined Inventory Receiving and Management

ShipBuddies uses barcode scanning and automated SKU validation to ensure every product is logged, tracked, and stored correctly the moment it arrives.

Benefits:

- 99.9% inventory accuracy.

- Real-time visibility through your client dashboard.

- Instant stock updates across all connected sales channels (Shopify, Amazon, Etsy, and more).

Result: No more overselling, manual counts, or out-of-stock surprises.

2. Automated Order Processing

Every order you receive, no matter the channel, is automatically imported into the ShipBuddies system. From there, it’s verified, prioritized, and routed to the optimal fulfillment center for fastest delivery.

Benefits:

- Instant order syncing and status updates.

- Intelligent routing reduces delivery zones and shipping costs.

- Minimal manual touchpoints, fewer errors.

3. Optimized Picking and Packing

ShipBuddies fulfillment center uses batch and zone picking strategies, supported by automation and barcode verification. This ensures accuracy and speed while maintaining brand consistency through customized packing.

Benefits:

- Fewer mispicks and faster throughput.

- Right-sized packaging reduces DIM-weight charges.

- Optional branded packaging available for a premium customer experience.

Impact: Up to 35% faster order processing compared to manual systems.

4. Multi-Carrier Shipping Optimization

ShipBuddies leverages carrier partnerships and real-time rate comparison to find the most cost-effective and reliable shipping options for each order.

Benefits:

- Access to discounted carrier rates.

- Intelligent carrier selection based on weight and location.

- Real-time shipment tracking through a centralized dashboard.

Result: Faster deliveries, lower costs, and happier customers.

5. Hassle-Free Returns and Reverse Logistics

Returns are part of ecommerce, but they don’t have to be painful. ShipBuddies’ automated Return Merchandise Authorization (RMA) system streamlines every step.

Benefits:

- Quick, trackable return processing.

- Instant restocking updates.

- Data insights into why returns happen — helping you improve products and reduce future returns.

6. Scalable Infrastructure Built for Growth

Whether you ship 100 or 10,000 orders per month, ShipBuddies scales with your business. Its distributed fulfillment network, automation, and integrated technology allow brands to expand without increasing overhead.

Key advantages:

- No warehouse leases or additional staff required.

- Flexible pricing, pay only for what you use.

- Seamless multi-location inventory control.

ShipBuddies Fulfillment Workflow Overview

| Workflow Stage | Traditional Approach | ShipBuddies Advantage |

| Inventory Receiving | Manual entry | Barcode automation |

| Order Processing | Manual verification | Auto-sync + smart routing |

| Picking & Packing | Human-only | Automated zones + barcode scans |

| Shipping | Single carrier | Multi-carrier optimization |

| Returns | Manual tracking | Automated RMA system |

In short: ShipBuddies replaces complexity with clarity. Your ecommerce orders are fulfilled accurately, shipped faster, and managed through one simple, transparent system.

FAQs About the Order Fulfillment Workflow

Before we wrap up, let’s answer some of the most common questions ecommerce sellers ask about fulfillment workflows, automation, and 3PL partnerships. These insights help clarify how to manage, measure, and scale your operations more effectively.

1. What is an order fulfillment workflow?

The order fulfillment workflow is the complete process of managing customer orders from purchase to delivery, including receiving inventory, processing orders, picking, packing, shipping, and handling returns. It ensures every order is fulfilled accurately and efficiently.

2. Why is the fulfillment workflow important for ecommerce sellers?

Your fulfillment process directly affects customer satisfaction, shipping speed, and profitability. A strong workflow keeps operations organized and scalable, while inefficiencies lead to delays, errors, and rising costs.

Tip: An optimized workflow can reduce fulfillment costs by up to 30% through automation and process improvement.

3. How many steps are in the fulfillment process?

Most ecommerce fulfillment workflows include six primary stages:

- Receiving inventory

- Order processing

- Picking items

- Packing orders

- Shipping and delivery

- Returns and reverse logistics

Each stage contributes to the customer experience and overall cost efficiency.

4. How does automation improve fulfillment?

Automation speeds up repetitive tasks and reduces manual errors. Systems like WMS (Warehouse Management Systems) automatically track inventory, sync orders from your store, generate shipping labels, and route orders to the nearest warehouse.

ShipBuddies uses automation to streamline these steps, ensuring faster turnaround times and real-time visibility.

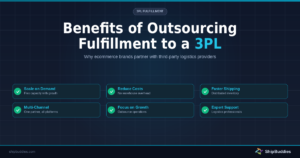

5. When should I outsource fulfillment to a 3PL provider?

You should consider outsourcing when:

- Order volume exceeds 500–1,000 orders per month.

- Labor or warehouse space becomes a bottleneck.

- You want to expand to multiple regions without opening new locations.

ShipBuddies, as a 3PL partner, provides the infrastructure, technology, and expertise needed to scale affordably.

6. How can I track fulfillment performance?

Track key metrics like:

- Cost per order (CPO)

- Order accuracy rate

- On-time delivery rate

- Return rate

7. How does ShipBuddies fit into my existing ecommerce system?

ShipBuddies integrates directly with popular platforms like Shopify, Amazon, WooCommerce, and Etsy. Your orders flow automatically into our system for processing, and tracking updates sync back to your store, giving you a seamless, automated fulfillment experience.

Pro Insight:

Successful ecommerce brands treat fulfillment as a competitive advantage, not a cost center. With automation and smart logistics, you can turn your operations into a growth engine, and ShipBuddies helps make that happen.

Build a Scalable Fulfillment Workflow with ShipBuddies

A great product gets you noticed, but a great fulfillment workflow keeps customers coming back. In ecommerce, fulfillment is where promises meet reality: the promise of fast delivery, accurate orders, and a brand experience that feels seamless from click to doorstep.

The brands that scale most successfully aren’t just selling more. They’re fulfilling smarter. They’ve built workflows that blend automation, data, and trusted logistics partners to eliminate inefficiency and elevate the customer experience.

That’s exactly what ShipBuddies delivers.

Why ShipBuddies Is the Smarter Way to Fulfill

ShipBuddies isn’t just a 3PL provider. It’s a technology-driven partner built to grow with your business. From automated inventory management to intelligent carrier selection, every part of the fulfillment process is optimized for speed, accuracy, and cost efficiency.

What you gain with ShipBuddies:

- Scalable infrastructure: Expand without warehouse leases or staffing overhead.

- Automated systems: Reduce manual tasks and improve accuracy with smart technology.

- Transparent pricing: Know exactly what you’re paying for, with no hidden fees.

- Data visibility: Access real-time reports and metrics on performance, cost, and delivery.

Result: Faster delivery, fewer errors, and a fulfillment system that grows effortlessly with your business.

Ready to Optimize Your Fulfillment Workflow?

If your ecommerce business is ready to:

✅ Ship faster

✅ Lower fulfillment costs

✅ Improve customer experience

✅ Scale with confidence

Then it’s time to let ShipBuddies take fulfillment off your plate.

Request a Free Fulfillment Workflow Audit

Schedule a Consultation with ShipBuddies

Final Thought: Your customers remember how fast you deliver, not how hard it was to make it happen. With ShipBuddies, fulfillment just works, smoothly, transparently, and at scale.