Your fulfillment model shapes everything: your costs, your control, your ability to scale, and ultimately, your customer experience. Choosing between third-party logistics (3PL), fourth-party logistics (4PL), and in-house fulfillment isn’t just a logistics decision. It’s a business strategy decision.

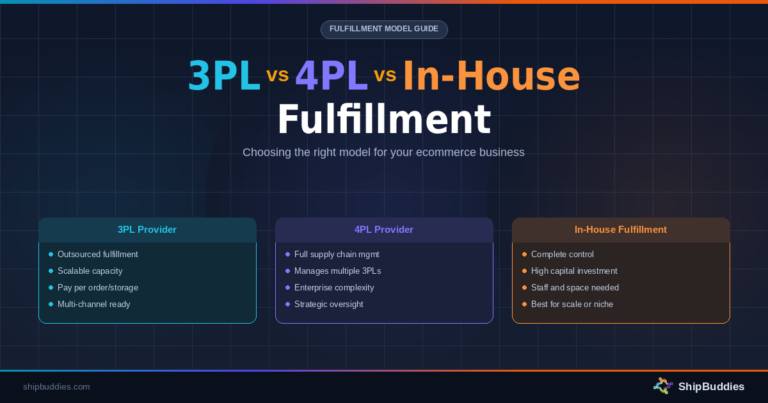

Here’s the short version: A 3PL handles your day-to-day fulfillment operations. A 4PL manages your entire supply chain strategy. In-house means you do it all yourself. Each model has trade-offs in cost, control, and scalability. The right choice depends on where your business is today and where you want it to go.

This guide breaks down what each model actually does, how they compare side by side, and how to figure out which one fits your situation. We’ll also cover the decision factors that matter most: order volume, growth plans, and capital.

Let’s start with the most common option for growing ecommerce brands.

What Is a 3PL (Third-Party Logistics Provider)?

A 3PL is an external partner that handles your day-to-day fulfillment operations. You send them your inventory. They store it, pick and pack orders, and ship them to your customers.

Think of a 3PL as your outsourced warehouse and shipping team. They handle the physical work: receiving inventory, managing stock, assembling orders, and coordinating with carriers. You retain control over your business strategy, product decisions, and customer relationships.

The core services a 3PL provides include:

- Warehousing: Storing your products in their facility

- Inventory management: Tracking stock levels, often with real-time visibility

- Pick and pack: Pulling items from shelves and packaging orders

- Shipping: Coordinating with carriers to get packages out the door

- Returns processing: Handling customer returns and restocking

What makes a 3PL provider different from a 4PL is the relationship. With a 3PL, you work directly with the company handling your products. There’s no middleman. You talk to the same team that’s packing your orders, which means faster communication and fewer layers between you and your fulfillment operations.

For most growing ecommerce brands, a 3PL hits the sweet spot between cost efficiency and operational control.

What Is a 4PL (Fourth-Party Logistics Provider)?

A 4PL, sometimes called a lead logistics provider (LLP), operates at a higher level. Instead of handling fulfillment directly, a 4PL manages your entire supply chain from a strategic perspective.

Here’s the key distinction: A 3PL executes. A 4PL orchestrates.

A 4PL doesn’t usually own warehouses or employ pick-and-pack staff. Instead, they coordinate multiple 3PLs, carriers, and technology platforms on your behalf. They act as a single point of contact for your entire logistics network, handling vendor relationships, contract negotiations, and supply chain optimization.

What a 4PL typically provides:

- Supply chain strategy: Designing and optimizing your logistics network

- Multi-provider coordination: Managing relationships with multiple 3PLs across regions

- Technology integration: Connecting systems across your supply chain

- Performance management: Tracking metrics and holding providers accountable

- Procurement and sourcing: Sometimes extending into supplier management

4PLs make sense for businesses with complex, multi-region supply chains that need someone to manage the whole picture. If you’re shipping from five warehouses across three countries using four different 3PLs, a 4PL can bring order to the chaos.

But there’s a trade-off. When you work with a 4PL, you’re adding a layer between you and your fulfillment operations. You might not know exactly who’s handling your products on any given day. For some businesses, that distance creates risk. It’s worth asking any 4PL provider about their subcontracting practices and whether you’ll have direct communication with the warehouses handling your inventory.

What Is In-House Fulfillment?

In-house fulfillment means your business owns and operates all fulfillment functions. Your warehouse. Your staff. Your technology. Your carrier relationships.

This model gives you total control over every aspect of the customer experience, from how products are stored to how they’re packed to what the unboxing looks like. If fulfillment is a core part of your brand identity (think luxury goods with custom packaging rituals), in-house operations let you maintain that standard without compromise.

Running in-house fulfillment requires:

- Physical space: A warehouse or fulfillment center (owned or leased)

- Staffing: Warehouse workers, a logistics manager, potentially a whole team

- Technology: A warehouse management system (WMS), inventory tracking, shipping software

- Carrier relationships: Direct accounts with UPS, FedEx, USPS, or regional carriers

- Equipment: Shelving, packing stations, forklifts, scanners

The appeal is clear: complete control, full visibility, and the ability to customize every detail of your order fulfillment workflow.

The reality is also clear: it’s expensive. You’re paying for that warehouse space whether you ship 100 orders or 10,000. You’re responsible for hiring, training, and managing staff. And when peak season hits, you’re limited by your four walls and your headcount.

In-house fulfillment works well at two ends of the spectrum: very small operations where the volume doesn’t justify outsourcing, and very large operations where the scale justifies dedicated infrastructure.

3PL vs 4PL vs In-House: Side-by-Side Comparison

Seeing these models next to each other makes the differences concrete. Here’s how they stack up across the factors that matter most:

| Factor | 3PL | 4PL | In-House |

| Primary function | Operational execution | Strategic supply chain management | Full internal control |

| Who handles fulfillment | Your 3PL partner | Other providers (coordinated by 4PL) | Your own team |

| Cost structure | Variable (pay for what you use) | Variable + management fee | Fixed (facility, staff, equipment) |

| Control level | Moderate (operations outsourced, strategy retained) | Low (strategy and operations outsourced) | Full |

| Scalability | High (3PL absorbs volume spikes) | High (network-based) | Limited by your facility |

| Best for | Growing ecommerce brands | Enterprise with complex multi-provider needs | Very low volume OR very high volume with unique needs |

| Capital required | Low | Low to moderate | High |

| Direct relationship | Yes (one partner) | No (4PL is intermediary) | N/A (internal) |

The cost structure difference deserves extra attention. With a 3PL, you convert fixed costs (warehouse lease, full-time staff salaries, equipment purchases) into variable costs (you pay per order, per pallet, per square foot used). That’s powerful for growing brands because your fulfillment costs scale with your revenue instead of requiring upfront capital investment.

In-house fulfillment flips that equation. You pay the same rent whether business is booming or slow. That’s a risk if demand is unpredictable. And let’s be honest, ecommerce demand is almost always unpredictable.

When to Use a 3PL

A 3PL makes sense when you’ve outgrown your garage but don’t need (or can’t afford) to build your own logistics infrastructure.

A 3PL is typically the right fit if:

- You’re processing more than 100 orders per month (the rough threshold where outsourcing becomes economically viable)

- You want to focus on growing your business rather than managing logistics

- Your order volume fluctuates seasonally or unpredictably

- You sell through multiple channels (Shopify, Amazon, TikTok Shop) and need unified fulfillment

- You don’t have the capital to invest in warehouse space, staff, and technology upfront

The flexibility of a 3PL is its biggest advantage. Need to ramp up for Black Friday? A good 3PL has the capacity. Hit a slow month? You’re not paying for empty warehouse space you don’t need.

Most ecommerce brands in the growth stage, somewhere between scrappy startup and enterprise giant, find that a 3PL provides the best balance of cost, control, and scalability. You get professional fulfillment infrastructure without the overhead of building it yourself.

When to Use a 4PL

A 4PL enters the picture when your supply chain gets too complex for a single fulfillment partner to manage.

A 4PL typically makes sense if:

- You’re processing 10,000+ orders per month across multiple regions

- You work with multiple 3PLs and carriers and need someone to coordinate them

- Your supply chain spans multiple countries with different compliance requirements

- You want to outsource logistics strategy, not just execution

- You need a single point of contact for a fragmented logistics network

Most small and mid-sized ecommerce businesses don’t need a 4PL. The added layer of management adds cost without proportionate benefit unless your operations genuinely require that level of coordination.

4PLs are built for enterprise complexity. If you’re a $50M+ brand with fulfillment centers on three continents, a 4PL can save you from managing dozens of provider relationships yourself. If you’re a $2M brand shipping from one location, you’ll probably find a 4PL is overkill. And expensive overkill at that.

When In-House Fulfillment Makes Sense

In-house fulfillment works at two ends of the volume spectrum, and for businesses with specific operational needs that outside providers can’t meet.

In-house makes sense if:

- You’re processing fewer than 100 orders per month, where outsourcing overhead doesn’t pencil out

- You’re a large, established brand (roughly $60M+ in revenue) where scale justifies dedicated infrastructure

- Your products require highly specialized handling or packaging that 3PLs can’t replicate

- Fulfillment is a core brand differentiator (luxury unboxing experiences, bespoke customization)

- You have existing warehouse space and staff that would otherwise be underutilized

The control in-house provides is real. You can make changes instantly. You can train staff on exactly how you want products handled. You can inspect every package before it goes out the door.

But that control comes with constraints. Your growth is capped by your physical capacity. Seasonal spikes mean either turning away orders or scrambling to hire temporary staff. And every hour you spend managing fulfillment is an hour you’re not spending on the parts of the business that drive growth.

For most growing ecommerce brands, the math eventually tips toward outsourcing. Not because in-house is bad, but because the opportunity cost of managing logistics internally becomes too high.

How to Choose the Right Fulfillment Model

The right model depends on your specific situation. Here’s a practical framework for thinking through the decision.

Consider Your Order Volume

Volume is the single biggest factor in this decision.

- Under 100 orders/month: In-house is usually simpler and more economical. The overhead of onboarding with a 3PL doesn’t make sense at this scale.

- 100 to 10,000 orders/month: This is 3PL territory. You have enough volume to benefit from professional fulfillment infrastructure but not so much that you need multi-provider coordination.

- 10,000+ orders/month: A 3PL still works, but if you’re shipping from multiple locations or dealing with complex multi-channel logistics, a 4PL might be worth evaluating.

These thresholds aren’t rigid. A brand doing 80 orders a month with rapid growth projections might onboard with a 3PL early to avoid a painful transition later. Context matters.

Evaluate Your Growth Plans

Where you’re headed matters as much as where you are.

If you’re planning aggressive growth, doubling or tripling sales over the next year, a 3PL gives you the flexibility to scale without infrastructure constraints. Your fulfillment partner absorbs the growth instead of you scrambling to hire and expand.

If your business is stable and predictable, you have more options. Stable demand means you can accurately size an in-house operation without as much risk.

If you’re expanding internationally, consider on-demand fulfillment models or multi-location 3PLs that can position inventory closer to your customers.

Assess Your Capital and Resources

This one’s straightforward: how much money and time can you invest?

Limited capital? A 3PL converts what would be major fixed costs into variable expenses. You’re not signing a warehouse lease or buying equipment. Your costs flex with your volume.

Significant capital and unique operational needs? In-house might be worth the investment, especially if you can build a fulfillment operation that becomes a competitive advantage.

Complex global operations but don’t want to manage multiple providers? A 4PL takes that coordination off your plate, for a price.

How ShipBuddies Works as a 3PL Partner

If a 3PL makes sense for your business, the next question is finding the right partner.

ShipBuddies operates as a focused, single-location 3PL built for growing ecommerce brands. That single-location model isn’t a limitation. It’s a feature. You get a direct relationship with the team handling your products. No subcontracting layers. No mystery about who’s packing your orders.

We integrate with the platforms you’re already selling on, including Shopify, Amazon, TikTok Shop, and others, so orders flow into fulfillment automatically. And because we’re built for flexibility, we can scale with you as your business grows without the complexity of managing multiple warehouse relationships.

Not sure if a 3PL is the right move? We’re happy to talk through your situation and help you figure out what makes sense, even if that means staying in-house for now. Learn more about our 3PL services or reach out to start a conversation.

Frequently Asked Questions

What is the main difference between 3PL and 4PL?

A 3PL handles day-to-day fulfillment operations: warehousing, picking, packing, and shipping. A 4PL acts as a strategic integrator, managing your entire supply chain and often coordinating multiple 3PLs on your behalf. The simplest way to think about it: a 3PL does the work, a 4PL manages the people doing the work.

Is a 3PL worth it for small businesses?

For most businesses processing more than 100 orders per month, a 3PL reduces costs and frees up time to focus on growth. Below that volume, the overhead of working with a 3PL may not be justified. The break-even point varies depending on your products, margins, and how you value your time.

What are the disadvantages of in-house fulfillment?

The main drawbacks are high capital requirements (facility, staff, technology), limited scalability during peak seasons, and the operational burden of managing logistics alongside your core business. In-house fulfillment also means you’re paying fixed costs regardless of order volume, a risk if demand is unpredictable.

When should a company use a 4PL instead of a 3PL?

A 4PL is typically suited for enterprise-level operations with complex, multi-region supply chains requiring coordination across multiple logistics providers. If you’re managing five warehouses across three countries with four different 3PLs, a 4PL can bring it together. Most small and mid-sized ecommerce brands are better served by a single 3PL relationship.

Can you switch from in-house to 3PL fulfillment?

Yes, and many brands make this transition as they grow. The key is documenting your current processes, including how you package products, label shipments, and handle returns, so your 3PL partner can replicate your standards. Most successful transitions happen during slower seasons to allow time for onboarding and working out kinks.

What’s the difference between 1PL, 2PL, 3PL, and 4PL?

The numbering refers to how many parties are involved in the logistics chain. 1PL is when a company handles its own logistics entirely. 2PL is when you hire a carrier (like UPS or FedEx) to transport goods. 3PL adds warehousing and fulfillment services. 4PL adds supply chain management and multi-provider coordination. In practice, most ecommerce discussions focus on 3PL vs. 4PL vs. in-house.

Bringing It All Together

Choosing a fulfillment model comes down to balancing cost, control, and scalability against your business’s current needs and future goals.

For most growing ecommerce brands, a 3PL offers the best combination: professional fulfillment infrastructure, flexible costs that scale with your business, and enough control to maintain your customer experience standards. You trade some direct oversight for the ability to focus on what actually grows your business.

4PLs have their place for enterprise operations managing complex, multi-region supply chains. In-house fulfillment works at the extremes: very early stage or very large scale, and for businesses where fulfillment is a genuine competitive differentiator.

The right answer isn’t universal. It depends on your order volume, your growth trajectory, your capital situation, and how much you value operational control. Start with where you are, plan for where you’re going.