Outsourcing fulfillment is the practice of contracting with a 3PL provider to handle warehousing, inventory management, pick and pack operations, shipping, and returns processing for an ecommerce business. Companies outsource these operations to eliminate the fixed costs of running their own warehouse while gaining access to logistics expertise, technology, and carrier relationships they could not build independently.

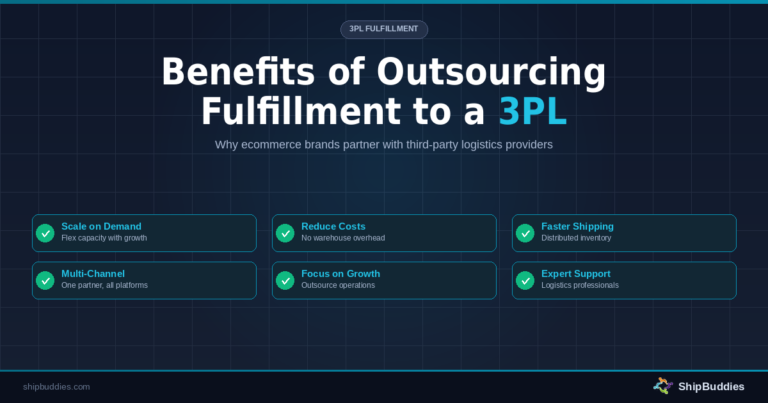

The benefits of outsourcing fulfillment extend far beyond simply handing off the work. Businesses that partner with a 3PL convert fixed overhead into variable costs, access bulk shipping discounts unavailable to individual shippers, and scale operations without capital investment. Research shows that 91% of companies using 3PLs report improved customer satisfaction, while 64% report reduced operating costs. These outcomes explain why 57% of ecommerce companies now outsource some or all of their fulfillment.

This article covers seven core benefits of outsourcing fulfillment: converting fixed costs to variable costs, accessing bulk shipping discounts, scaling without capital investment, reclaiming time for core business activities, gaining technology without upfront investment, reaching new markets through geographic networks, and reducing operational risk. It also addresses what you trade off when outsourcing and how to determine if the timing is right for your business.

The first benefit addresses what most business owners care about most: the money.

Convert Fixed Costs to Variable Costs

Outsourcing fulfillment transforms your cost structure from fixed overhead to variable, usage-based fees. Instead of paying for warehouse space, equipment, and labor regardless of order volume, you pay only for the storage and services you use.

In-house fulfillment requires significant fixed investments. Warehouse leases run $15 to $30 per square meter annually, plus utilities, insurance, and maintenance. Equipment costs include shelving, packing stations, forklifts, and shipping workstations. Labor costs demand full-time employees whether you ship 50 orders or 500.

A 3PL provider absorbs these fixed costs across multiple clients. You pay per pallet stored, per order picked and packed, and per package shipped. When order volume drops, costs drop with it. When volume spikes, you scale up without renegotiating leases or hiring staff.

The financial impact is measurable. A 2025 study by Armstrong & Associates found that shippers saved 18% to 25% in capital expenditures over three years by outsourcing warehousing and fulfillment. Amazon MCF reports that 64% of companies using 3PLs say doing so reduced their operating costs.

This variable cost structure becomes especially valuable during slow periods. You avoid paying for empty warehouse space and idle employees. For a detailed breakdown of what fulfillment actually costs, see our guide to fulfillment cost breakdown.

The savings extend beyond warehousing. Outsourcing also unlocks shipping discounts that small and mid-sized businesses cannot access alone.

Access Bulk Shipping Discounts

3PL providers ship millions of packages annually and negotiate carrier rates at volumes individual businesses cannot match. These bulk discounts translate directly to lower shipping costs for their clients.

Small and mid-sized ecommerce businesses pay retail or near-retail shipping rates when shipping independently. Carriers reserve their best pricing for high-volume shippers. A business shipping 500 packages monthly has no leverage to negotiate. A 3PL shipping 500,000 packages monthly has significant leverage.

The savings are substantial. Industry data shows that outsourcing fulfillment can reduce shipping costs by 15% to 35% through bulk discounts alone. For a business spending $50,000 annually on shipping, that represents $7,500 to $17,500 in savings.

3PLs also optimize shipping through zone-based strategies. By distributing inventory across multiple warehouses, they reduce the distance packages travel. Shorter distances mean lower zone charges. A package shipped from a nearby warehouse costs less than one shipped cross-country.

Multi-carrier access adds another layer of savings. Rather than being locked into one carrier’s rates, 3PLs compare options across UPS, FedEx, USPS, and regional carriers for each shipment. This rate shopping ensures the best price for each package based on size, weight, destination, and delivery speed.

For more on optimizing shipping operations, see our shipping optimization guide.

Cost savings matter, but growth matters more. The next benefit addresses how outsourcing enables expansion without requiring expansion.

Scale Without Capital Investment

Outsourcing fulfillment allows businesses to handle growth and seasonal demand spikes without investing in additional infrastructure, equipment, or permanent staff.

Ecommerce businesses face dramatic seasonal fluctuations. For many, Q4 represents 40% to 60% of annual order volume. Black Friday, Cyber Monday, and holiday shopping create demand spikes that would overwhelm most in-house operations.

Building internal capacity for peak demand means maintaining excess capacity during slow periods. If your December volume is three times your July volume, you either under-serve customers in December or over-invest in infrastructure for July.

3PL providers solve this problem through shared capacity. They staff and equip their warehouses to handle peak demand across all clients. When your orders spike, you use more of their capacity. When orders slow, you use less. You never pay for warehouse space sitting empty.

This flexibility extends beyond seasonal peaks. Product launches, viral marketing moments, and unexpected demand surges all require rapid scaling. A 3PL can absorb these spikes without advance notice. Building this responsiveness internally would require maintaining permanent excess capacity.

The adoption data reflects this value. Industry research shows that 57% of ecommerce companies now outsource some or all fulfillment operations. Among Fortune 500 companies, 90% use 3PL providers. Large enterprises reach this conclusion earlier, but growing businesses increasingly follow.

For businesses experiencing unpredictable demand, on-demand fulfillment provides even greater flexibility.

Scaling operations is only valuable if you have time to focus on what drives growth. That brings us to the next benefit.

Reclaim Time for Core Business Activities

Outsourcing fulfillment frees business owners and teams to focus on product development, marketing, sales, and customer relationships instead of logistics operations.

Fulfillment is time-intensive. Receiving inventory, organizing storage, picking orders, packing shipments, printing labels, scheduling carrier pickups, and handling customer inquiries about shipping all consume hours that could drive revenue. For many founders, fulfillment becomes a second full-time job.

This time trade-off has real costs. Every hour spent packing boxes is an hour not spent improving products, creating marketing content, or building customer relationships. The opportunity cost compounds as the business grows.

3PL partnerships eliminate this burden. The logistics experts handle the operational details while you handle the strategic work. Product sourcing, brand building, customer acquisition, and market expansion all require focused attention that logistics operations crowd out.

The psychological benefit matters too. Knowing that orders will ship correctly and on time, without your direct involvement, removes a persistent source of stress. Business owners report greater clarity and focus when fulfillment no longer occupies mental bandwidth.

You did not start your business to become a warehouse manager. Outsourcing returns your attention to whatever you did start it for.

For a deeper look at the fulfillment process itself, see our ecommerce fulfillment overview.

Beyond time savings, outsourcing provides access to capabilities most businesses cannot build independently. Technology is the clearest example.

Gain Technology Without Upfront Investment

3PL providers invest in warehouse management systems, inventory tracking technology, and platform integrations that would be cost-prohibitive for individual businesses to implement.

Modern fulfillment requires sophisticated technology. Warehouse management systems coordinate receiving, storage, picking, packing, and shipping. Real-time inventory tracking prevents overselling and stockouts. Platform integrations sync orders from Shopify, Amazon, WooCommerce, and other sales channels automatically.

Building this technology stack internally requires significant capital. A warehouse management system alone can cost $50,000 to $500,000 to implement, plus ongoing licensing and maintenance. Integration development, barcode systems, and reporting tools add to the investment.

3PLs spread these technology costs across all clients. You gain access to enterprise-grade systems without enterprise-grade budgets. The same technology that powers large retailers becomes available to growing businesses.

The capabilities extend beyond basic operations. Advanced 3PLs offer demand forecasting, inventory optimization, and analytics reporting. These tools help businesses make better decisions about purchasing, pricing, and marketing.

Industry surveys confirm that technology matters. Research shows 93% of shippers say strong IT capabilities are critical when selecting a 3PL partner. Real-time visibility into inventory and orders has become an expectation, not a differentiator.

Technology enables better operations. Geographic reach enables better customer experience.

Reach New Markets Through Geographic Network

3PL providers operate warehouse networks across multiple regions, allowing businesses to position inventory closer to customers and reduce shipping time and cost.

Geography directly impacts both delivery speed and shipping expense. A package shipped from New Jersey to California crosses multiple shipping zones and takes longer than one shipped from a California warehouse. Customers in California receive their orders faster, and the business pays less for shipping.

Building a multi-warehouse network independently requires enormous capital. Leasing space in multiple regions, staffing each location, and coordinating inventory across facilities creates complexity most businesses cannot manage.

3PLs already operate these networks. By partnering with a provider that has warehouses in strategic locations, businesses gain national or international reach without building anything. Inventory distributed across the network ships from the closest location to each customer.

The customer experience impact is significant. Research shows that 92% of consumers expect delivery within two to three days. Meeting this expectation from a single location requires expensive expedited shipping. Meeting it from distributed locations requires only standard ground service.

This capability supports market expansion. Entering new geographic markets becomes simpler when fulfillment infrastructure already exists there. International expansion, which would otherwise require establishing foreign operations, becomes a matter of routing inventory to an existing 3PL facility.

North American ecommerce brands show the highest 3PL adoption rates at 46%, driven partly by the geographic advantages these networks provide.

Geographic reach addresses growth. The next benefit addresses protection.

Reduce Risk and Ensure Business Continuity

Outsourcing fulfillment transfers operational risks to partners with the infrastructure, insurance, and contingency plans to manage them.

Warehouse operations carry inherent risks. Equipment failures, facility damage, inventory loss, and workplace accidents all create liability. Managing these risks requires insurance, safety programs, compliance expertise, and contingency planning.

Labor presents particular risk in current markets. The U.S. Bureau of Labor Statistics reports warehouse labor turnover rates above 46% annually. Hiring, training, and retaining warehouse staff is an ongoing challenge. Labor shortages during peak seasons can cripple fulfillment operations.

3PL providers absorb these workforce challenges. They maintain staffing levels across demand cycles and handle recruitment, training, and retention. When you outsource, labor headaches become their problem, not yours.

Business continuity planning adds another layer of protection. What happens if your warehouse floods, loses power, or faces a major equipment failure? 3PLs have disaster recovery plans, backup systems, and often multiple facilities to route around problems.

Insurance and liability coverage shift as well. The 3PL carries insurance on inventory in their care and liability for their operations. Your risk exposure decreases when professionals manage the physical operations.

For businesses where returns processing adds complexity, see our guide to reverse logistics.

The benefits are substantial, but outsourcing involves trade-offs. Understanding what you give up helps make an informed decision.

What You Trade Off When Outsourcing Fulfillment

Outsourcing fulfillment reduces direct control over several aspects of operations. Understanding these trade-offs helps set realistic expectations.

Packaging and unboxing experience become harder to customize. While many 3PLs offer branded packaging options, the level of customization available in-house exceeds what most fulfillment centers can efficiently provide. Businesses with highly distinctive unboxing experiences may find this limiting.

Communication adds a layer of dependency. When customers have shipping questions or problems arise, resolution involves coordinating with an external partner rather than walking to the warehouse. Response times depend partly on the 3PL’s customer service quality.

Last-minute operational changes become more difficult. Changing how orders are packed, adding inserts, or modifying fulfillment rules requires coordination rather than simply telling your warehouse team. Flexibility decreases when operations happen elsewhere.

Some businesses should not outsource, at least not yet. Very low order volumes may not justify the cost. Highly customized products requiring special handling may not fit standard 3PL processes. Businesses with existing warehouse infrastructure and expertise may operate more efficiently in-house.

For a detailed comparison of the options, see our guide to3PL vs. in-house fulfillment.

Understanding the trade-offs leads to the practical question: when does outsourcing make sense for your business?

When to Outsource Fulfillment

Several indicators signal that outsourcing fulfillment may be the right move. These relate to order volume, operational strain, and strategic priorities.

Order volume thresholds provide rough guidance. Many businesses begin feeling strain at 10 to 20 orders per day, when fulfillment starts consuming significant time. The break-even point where outsourcing becomes cost-effective typically falls between 1,000 and 3,000 monthly orders, depending on product characteristics.

Space constraints create clear signals. When inventory outgrows your garage, spare room, or current warehouse, the choice becomes expansion or outsourcing. Commercial warehouse expansion requires lease commitments and capital investment. Outsourcing requires only a partnership agreement.

Time allocation reveals priorities. If fulfillment consumes more than 20% of your working hours, or if you consistently sacrifice strategic work for operational tasks, the opportunity cost may exceed the cost of outsourcing.

Shipping costs eating into margins suggests another indicator. If you cannot compete on delivery speed or free shipping thresholds because your shipping costs are too high, a 3PL’s bulk discounts may restore profitability.

Seasonal stress tests capacity. If peak seasons overwhelm your operation, resulting in delayed shipments and customer complaints, you either build excess capacity or partner with someone who already has it.

Ask yourself these questions:

- Is fulfillment preventing me from focusing on growth activities?

- Do I have the capital and desire to build warehouse infrastructure?

- Can I handle demand spikes with current resources?

- Are my shipping costs competitive?

If the answers point toward constraints, outsourcing addresses them without requiring you to become a logistics company.

Frequently Asked Questions

Is outsourcing fulfillment worth it?

For most growing ecommerce businesses, outsourcing fulfillment delivers measurable value. Companies report 15% to 35% shipping savings through bulk discounts, and 64% report reduced operating costs overall. The 91% customer satisfaction improvement rate suggests the operational benefits translate to customer experience. The break-even point typically occurs between 1,000 and 3,000 monthly orders.

How much can you save by outsourcing to a 3PL?

Savings vary by business, but common ranges include 15% to 35% on shipping through bulk carrier discounts, 18% to 25% on capital expenditures over three years by avoiding infrastructure investment, and significant labor cost reduction by eliminating warehouse staff management. A business spending $100,000 annually on fulfillment-related costs might save $15,000 to $30,000 through a well-matched 3PL partnership.

What are the disadvantages of outsourcing fulfillment?

Trade-offs include reduced direct control over packaging and unboxing experience, communication dependency with your fulfillment partner, and less flexibility for last-minute operational changes. Some businesses also experience a learning curve during the transition period. These drawbacks are manageable with the right 3PL relationship and clear communication.

When should a business outsource fulfillment?

Consider outsourcing when order volume strains your capacity (typically 10 to 20 or more daily orders), inventory outgrows available space, fulfillment consumes more than 20% of your time, or shipping costs eat into margins. Seasonal demand that overwhelms your operation is another clear indicator.

Can small businesses benefit from outsourcing fulfillment?

Small businesses can benefit from outsourcing fulfillment, particularly after reaching sufficient order volume to make the partnership cost-effective. Many 3PLs serve small businesses with flexible pricing structures. The key threshold is typically 100 or more monthly orders, though this varies by product type and complexity.

How ShipBuddies Delivers These Benefits

ShipBuddies provides the benefits outlined in this article through flexible, technology-driven fulfillment services designed for growing ecommerce brands.

Our warehouse network positions inventory close to your customers, reducing shipping costs and transit times. Real-time inventory visibility through our platform integration keeps your sales channels synchronized. Bulk carrier relationships provide shipping discounts that improve your margins.

We handle the operational complexity so you can focus on building your brand. From receiving and storage through pick, pack, ship, and returns processing, our team manages the logistics while you manage the growth.

Ready to see how outsourcing fulfillment could work for your business? Request a quote to discuss your specific needs and volume.