Introduction

Shipping costs can be one of the most frustrating variables in ecommerce logistics, especially when those costs are driven not by the weight of a product, but by the size of its packaging. This is where dimensional weight, also known as DIM weight, comes into play. Carriers like UPS, FedEx, and USPS use DIM weight pricing to account for the space a package occupies during transit, which means large, lightweight packages can cost significantly more to ship than expected.

For growing ecommerce businesses, optimizing packaging is one of the most effective ways to control these costs. Reducing dimensional weight not only cuts down on shipping expenses but also improves packaging efficiency, lowers material usage, and enhances customer experience.

In this article, we’ll break down what dimensional weight is, why it matters, and share practical packaging strategies that can help you reduce it. From right-sizing your boxes to leveraging automation tools, these packaging hacks are designed to make your fulfillment process leaner, smarter, and more cost-effective.

Understanding Dimensional Weight

Dimensional weight, or DIM weight, is a pricing technique used by shipping carriers to account for the space a package takes up during transit, not just its actual weight. In many cases, a lightweight item in a large box can cost more to ship than a heavier, more compact item. Understanding how DIM weight is calculated and why it impacts shipping costs is essential for any business looking to reduce fulfillment expenses.

How Dimensional Weight Is Calculated

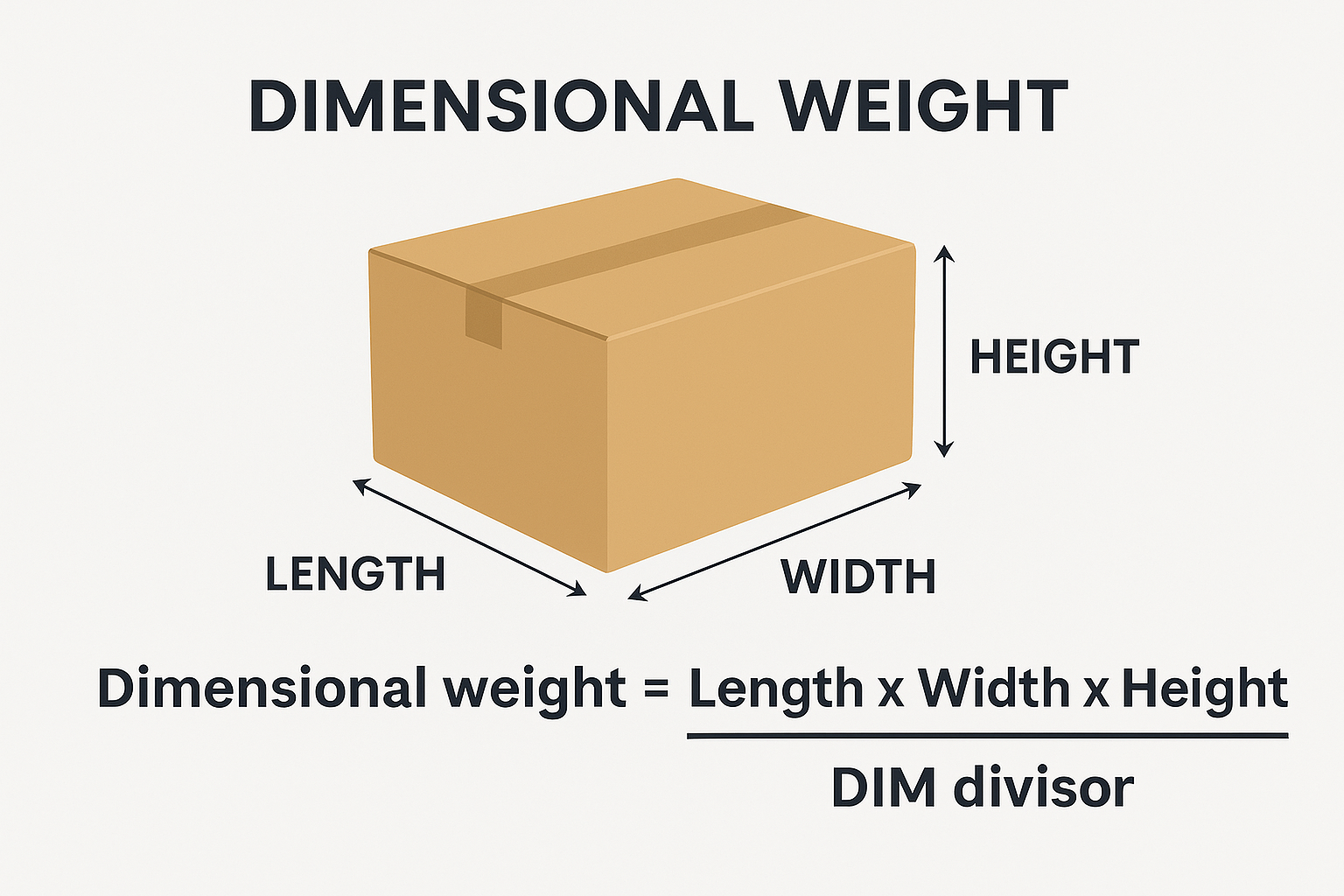

Carriers like UPS, FedEx, and USPS calculate dimensional weight using a standard formula:

DIM weight = (Length × Width × Height) ÷ DIM divisor

The DIM divisor is a number set by the carrier, often 139 for domestic shipments in inches. If the dimensional weight is greater than the actual weight, the shipping cost is based on the higher DIM weight instead.

Example:

If a package measures 20 x 14 x 10 inches:

20 × 14 × 10 = 2,800 cubic inches

2,800 ÷ 139 = 20.14 pounds (DIM weight)

If the actual weight is 10 pounds, you’ll be charged for 20 pounds.

To make it easier to calculate DIM weight for your own products, use the ShipBuddies free DIM weight calculator. Just enter your package dimensions and get instant results based on standard carrier formulas.

Why Carriers Use DIM Weight

Shipping carriers have limited space in delivery vehicles and cargo holds. DIM weight ensures that businesses are charged fairly based on both size and weight. It prevents oversized, low-weight shipments from taking up valuable space without paying for their share of the shipping capacity.

When DIM Weight Affects You

DIM weight pricing is commonly applied when:

- Packages are large in volume but light in weight

- Shipping air or expedited services

- Using branded or standard boxes that are not right-sized to the product

- Fulfillment operations don’t optimize packaging efficiency

Sellers who ignore DIM weight may unknowingly inflate their shipping costs, especially at higher volumes. This is why evaluating and adjusting your packaging strategy is critical to cost control.

Packaging Hacks to Reduce DIM Weight

Minimizing dimensional weight starts with smart, strategic packaging decisions. Here are five practical tactics you can implement to reduce package size and avoid inflated shipping charges.

1. Right-Size Your Packaging

Using boxes that are too large for your products is one of the most common causes of high dimensional weight charges. By switching to packaging that fits your products more precisely, you reduce the overall volume of each shipment.

- Keep multiple box sizes on hand to match your most frequently shipped items

- Avoid using filler material to compensate for oversized boxes

- Consider telescoping boxes or adjustable cartons for items with variable sizes

Right-sizing is a simple change that can yield immediate savings.

2. Switch to Mailers When Appropriate

Not every product needs to be shipped in a box. For soft goods like clothing, accessories, and other non-fragile items, poly mailers or padded envelopes take up less space and often weigh less than traditional packaging.

- Use poly mailers for soft, durable items

- Choose padded mailers for items that need minimal protection

- Compress items to reduce thickness before sealing mailers

Mailers help lower both actual and dimensional weight and are ideal for high-volume, lightweight products.

3. Reduce Unnecessary Internal Packaging

Excess packaging inside the box can increase dimensions and contribute to waste. Streamlining what goes inside your package helps minimize size and weight.

- Eliminate oversized inserts or bulky protective materials

- Replace bubble wrap and foam with recycled paper or molded pulp

- Use product-specific inserts that reduce shifting without adding volume

Efficient internal packaging keeps your product protected without driving up shipping costs.

4. Bundle Items Smarter

If you sell multiple items per order or offer kits and subscriptions, bundling them in a compact, thoughtful way can help reduce your package footprint.

- Design bundle layouts that maximize space efficiency

- Use inserts or trays that hold items tightly without wasted space

- Avoid separate boxes within the main carton unless absolutely necessary

Smarter bundling minimizes air gaps and leads to a more compact shipment.

5. Explore Custom Packaging Options

If your current packaging consistently leads to dimensional weight surcharges, it may be time to consider custom solutions. A packaging provider can design boxes or mailers that fit your exact product dimensions.

- Request dielines or prototypes based on your SKUs

- Use historical shipping data to guide packaging design decisions

- Factor in long-term savings from reduced shipping fees

While custom packaging requires upfront investment, it pays off in operational efficiency and brand presentation.

Benefits of Reducing DIM Weight

Reducing dimensional weight is one of the most effective ways to cut shipping costs and increase fulfillment efficiency. But the advantages go beyond lower carrier fees. Businesses that invest in smarter packaging strategies can also improve sustainability, enhance customer satisfaction, and boost profit margins.

Here are the key benefits of reducing DIM weight:

Lower Shipping Costs

Shipping carriers calculate fees based on either the actual weight or dimensional weight, whichever is greater. When your packaging is more compact, it is more likely that your shipping cost will reflect the actual weight instead of a higher dimensional weight. This can lead to:

- Immediate cost savings on every shipment

- Lower surcharges for oversized packages

- Better carrier rate negotiation over time

For high-volume sellers, these savings can add up quickly and significantly impact the bottom line.

Reduced Packaging Material Use

Optimizing packaging dimensions allows you to use fewer materials, which cuts down on costs for boxes, filler, and tape. It also means you’ll require less storage space for supplies and spend less time prepping each order.

- Fewer packaging supplies purchased over time

- Lower storage and warehouse handling costs

- Streamlined packing process with less waste

This efficiency benefits both your budget and your operations.

Faster Fulfillment Workflows

Smaller, simpler packages are easier and quicker to handle. Whether you’re fulfilling orders in-house or through a third-party logistics partner, right-sized packaging reduces the time it takes to pick, pack, and ship orders.

- Shorter packing times

- Easier stacking, storing, and transporting

- Faster carrier pickup and processing

When fulfillment is faster, you can ship more orders per day and improve delivery speed.

Improved Sustainability

Less packaging and more efficient shipping contribute to a greener operation. Smaller packages mean fewer delivery trucks, lower fuel consumption, and reduced waste.

- Decreased carbon footprint from transportation

- Less packaging waste sent to landfills

- Stronger appeal to eco-conscious consumers

Sustainability is increasingly important to shoppers, and DIM weight reduction supports more environmentally responsible practices.

Better Customer Experience

Oversized packaging can frustrate customers, especially when it contains a small item floating in a sea of filler. Compact, efficient packaging is easier to open, more attractive, and reflects a higher level of care.

- Clean, professional unboxing experience

- Lower risk of damage from shifting during transit

- Positive brand impression that can drive repeat purchases

Customers notice the difference, and they appreciate businesses that ship responsibly and efficiently.

How ShipBuddies Can Help

Dimensional weight is a hidden cost that can quietly drain profit margins if not addressed. For ecommerce businesses shipping high volumes of lightweight or irregularly sized products, optimizing packaging is not just a nice-to-have. It is a must. By implementing smart packaging practices such as right-sizing boxes, switching to mailers, reducing excess materials, and bundling efficiently, you can significantly lower your DIM weight charges and improve the overall efficiency of your fulfillment operation.

The benefits go beyond cost savings. Lower DIM weight leads to faster packing times, a cleaner unboxing experience, and a more sustainable supply chain. It also sets your brand apart as one that values both operational excellence and customer satisfaction.

At ShipBuddies, we help businesses turn fulfillment into a competitive advantage. From packaging optimization to intelligent inventory handling, we make it easy to reduce dimensional weight and streamline shipping without sacrificing quality or control.

Ready to reduce your shipping costs and ship smarter? Reach out to ShipBuddies today to learn how we can help you build a more efficient, cost-effective fulfillment process.